A nondestructive examination method used to:

- Evaluate an item by observation.

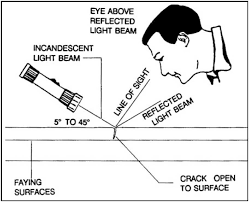

- Determine the surface condition of an article,

- Check the alignment of mating surfaces, compliance with physical requirements (dimensions, settings), etc.

- Usually the first method employed for locating suspected defects

Why Visual Examination?

Can be used to inspect:

- The surface

- Breaking discontinuities

- Cracks

- Holes

- Corrosion

- Does not require special equipment other than good eyesight(optical and mechanical aids is optional to improve inspection quality)

- Low cost

Visual Inspection Optical Aids

Used when direct visual examination is not possible

- Microscopes

- Borescopes

- Fiberscopes

- Video Cameras

Visual Inspection Mechanical Aids:

- Micrometers

- Calipers

- Depth gauges

- Thread pitch gauges

- Feeler gauges

- Weld gauges

- Mirror